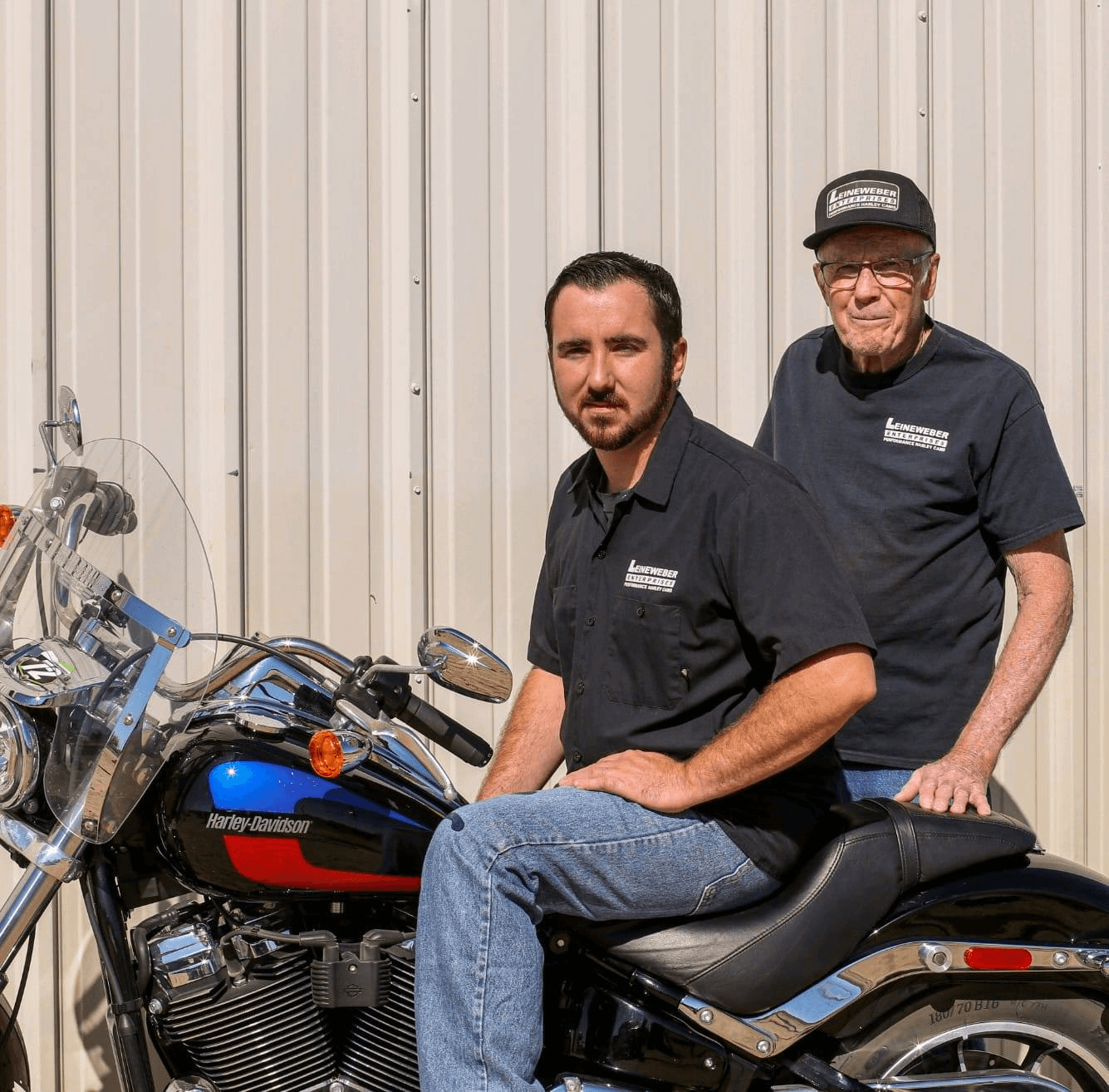

Inside their machine shop in Johnson Valley, California, Jim Leineweber and his son Justin spent years perfecting their high-performance camshafts, paving the way for their legacy.

With over 70 years of experience, Jim spent his career producing nothing less than high-quality stock and performance upgrade Harley camshafts, which have been the hallmark of the Leineweber Enterprises reputation for nearly 50 years.

As a racer, teacher, entrepreneur, brother, father, grandfather, and more, it saddens us to hear of Jim’s recent passing. With such an impressive performance history of Leineweber cams, Jim was an inspiration to many and nothing short of an innovator.

Jim’s family has publicly expressed their loss, paying tribute to the “many talks in the shop, all of the teaching, all of the good times and his many lessons”. As the motorcycle and Harley-Davidson community mourn this loss, it is an understatement to say that the performance industry is and will be forever changed from the work of Jim Leineweber.

In paying tribute to Jim’s legacy, we want to take this opportunity to explore the history of Leineweber Enterprises, what they have accomplished, and how you can continue to support their quality performance parts.

History of Leineweber Enterprises

With a passion for quality parts for high-performance rides, Jim worked on and with motorcycles for most of his life.

Despite the reputation Leineweber Enterprises built for themselves, they never found the need for sophisticated forming and grinding equipment in some hot-shot laboratory. Instead, they preferred to stick to their roots as a family run business and work from their own machine shop.

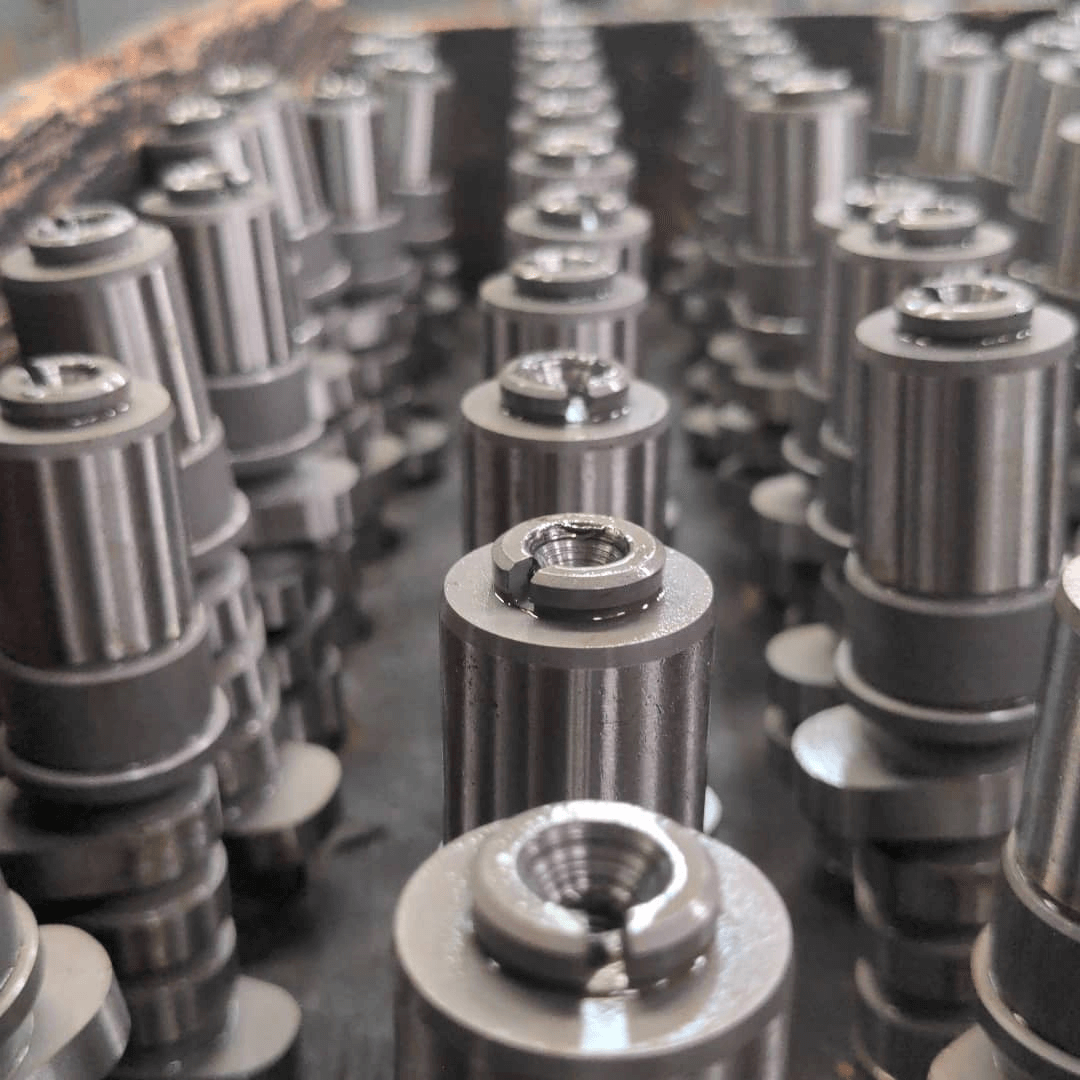

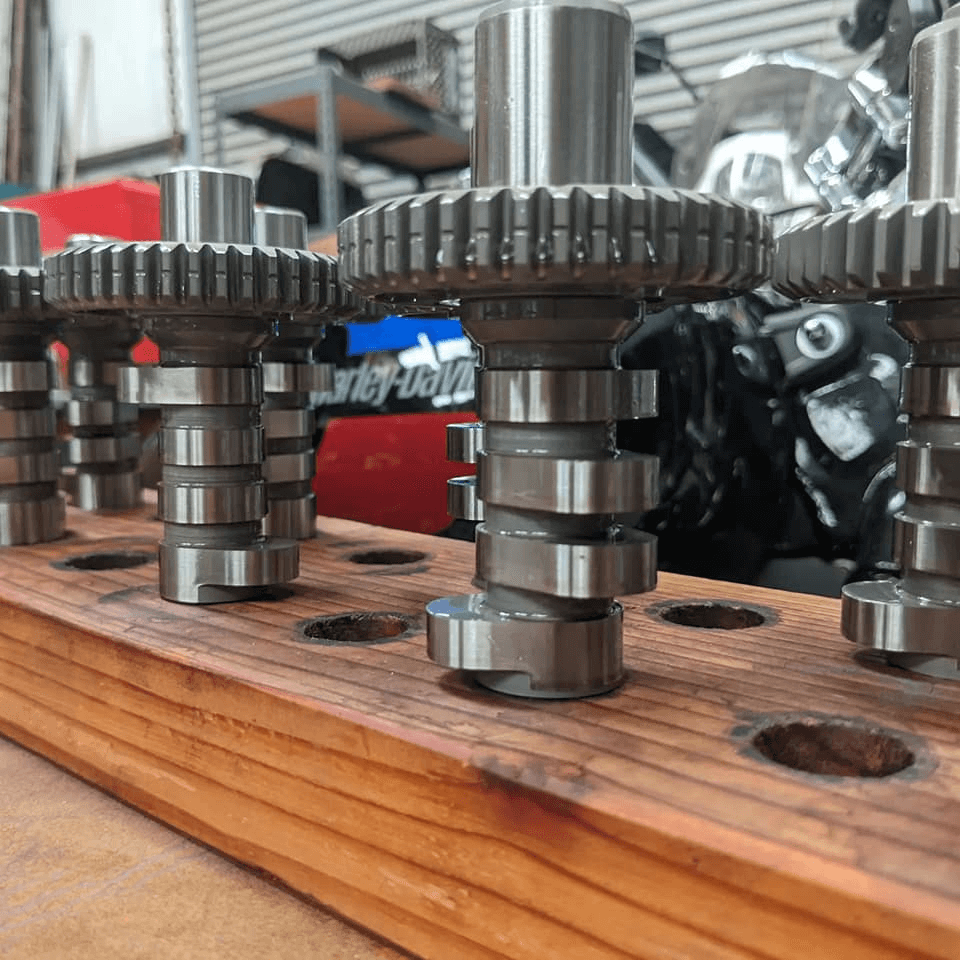

Relying on skill, experience and craftsmanship, Jim and Justin began their spectacular grinds on some rather unspectacular looking equipment. They pride themselves on manufacturing all of their camshafts with heat-treated aircraft quality materials, with their gear pressed on in a conventional manner to produce more power than any other cams on the market.

Their valve timing is checked at an impressive .053″, and their range stretches across TwinCams with a 1.62-1 rocker ratio right back through Evo, Sportsters, Shovelheads, Panheads to 1-1 ratio Knucklehead cams.

Always looking for ways to innovate, they continued to offer a custom cam grinding service, restoration cams, cams for Flatheads and cams for supercharged and turbocharged race engines.

Continuing to make a name for themselves, dealers can and have been ordering direct from Leieweber Enterprises from all across Europe, Australia and the United States.

Leinenweber Enterprises Services

While offering global, quality camshafts is their legacy, who are Leineweber Enterprises and what do they offer today?

Camshafts

Virtually every four-stroke internal-combustion engine has a camshaft, opening and closing the engine’s intake and exhaust valves. While they seem relatively simple, they can dramatically affect how your vehicle performs at different engine speeds.

Passionate about quality and performance, Leinenweber Enterprises specialise in all things camshafts. In fact, their high-quality production of camshafts is what the business is known for.

There are many different camshafts on the market, but ultimately, they all fall under two categories; flat tappet or roller and are either solid or hydraulic. The main difference between this hydraulic roller and the hydraulic flat tappet camshaft is that the roller is made of steel, and the flat tappet is chilled iron casting.

As the name suggests, roller cams use a lifter with a roller on them. While it may look like a flat tappet, it has wider lobes to connect differently to the lifter and is intended to reduce friction, increase RPM potential and allow higher valve spring pressures to be used.

On the other hand, flat tappets can only withstand limited valve spring pressure pushing the lifter against the cam lobe. As the valve spring pressure on the flat tappet increases, you increase wear on the cam lobe and the cam contact face of the lifter.

Leineweber produces camshafts of the constant velocity type, which lifts the valve very quickly to its maximum lift. These camshafts are built for:

- Twin cams

- Evolutions

- Shovelheads and Panheads

- Sportsters

- Knuckleheads

- Flatheads

They also produce high-performance valve train components and restorations for flatheads.

Quality manufacturing

While the passing of Jim has been unexpected and undoubtedly difficult for the rest of the family and business, Justin is continuing business in Jim’s footsteps. Jim’s wife, Joyce Wheeler, also passed last year, another devastating loss for the family and the Johnson Valley motorcycle community. Looking forward, Justin publicly responded, saying, “we are putting one foot in front of the other keeping everything going in their honour”.

Looking to continue making his family proud, no doubt, all Leineweber Camshafts will continue to be manufactured in the United States of America from the same high-quality materials.

The camshafts that Leineweber have already produced are the constant velocity type, which lifts the valve very quickly to its maximum lift. Built for performance, these valves are at or near maximum lift for most of the duration, creating a wider torque range.

If it isn’t already clear to tell, the business is built and grounded within family foundations, which translates into how they treat their customers with no exceptions. Also built on a passion for the iconic Harley-Davidson motorcycles, you can continue to rely on Leinenweber Enterprises for quality parts.

Build Your Dream Bike with Taverner Motorsports

As Harley-Davidson enthusiasts; we greatly value Jim Leinweber’s contribution to the industry. Like Jim himself, we also pride ourselves on innovation, passion and dedication to the highest quality parts and products.

Since 1975, Taverner has prioritised stocking an extensive library of parts from worldwide suppliers and partners to create one of a kind custom builds and restorations. We live up to our name by sourcing from only the best, guaranteeing our customers receive the highest quality services every time.

To see how our services live up to our name, you can contact us for more information on 07 3148 5288, visit our workshop in Bowen Hills, or request a quote online. If you’re looking to learn more about what we do and the brands we support, you can browse the Taverner blog, our hub for motorcycle enthusiasts.